- GST No. 06AURPS2013E1ZQ

- Send SMS

- Send Email

Automation Services

Leading Manufacturers, Exporters, Wholesaler and Retailer of Pump Meter Automation Services, PumpDrive Automation Services, Software Test Automation Services, Sonolyzer Automation Services and Supreme Automation Services from Karnal.

Preferred Buyer From

| Location | India ( Haryana only) & All other countries |

PumpMeter. Gain a deeper insight into your pump.

Is your pump operating in an efficient and cost-saving manner? The innovative PumpMeter pump monitoring unit identifies the current operating point and measures all key data of the pump. Its EFF energy efficiency icon signals potential for energy savings.

KSB's PumpMeter clearly shows you whether your pump is operating in its optimum. It measures the suction and discharge pressures of your pump around the clock and establishes the pump’s operating point based on the differential pressure. The direct connection to your process control system allows you to have central access to all relevant data. This helps you decide on where to implement optimisation measures and save.

PumpMeter replaces the pressure gauges upstream and downstream of the pump, the pressure transmitter for the control functions, as well as any additional monitoring equipment. The direct connection to your process control system allows you to have central access to all relevant data. This helps you decide on where to implement optimisation measures and save.

Optimisation at a glance

- For optimum monitoring the easy-to-read display on KSB's PumpMeter alternates between measured and calculated values. After a few operating hours the EFF energy efficiency icon will appear on the display to indicate potential energy savings:

- KSB's PumpMeter thoroughly monitors the pumps of the Eta type series and continuously analyses their operating data. The recorded load profile demonstrates where savings can be made:

- On the Etaline close-coupled heating pump PumpMeter indicates whether energy can be saved with a variable speed system:

- PumpMeter also enables the economical and efficient operation of the Etaline Z in-line twin pump comprising two separate centrifugal pumps in one pump casing:

Pump Operation Check (POC) identifies the best solution for optimised operation

If PumpMeter indicates optimisation potential, then it's worth doing a Pump Operation Check. KSB’s energy efficiency experts use the load profile measured by the pump monitoring unit as a basis and provide concrete recommendations for action to increase the availability and efficiency of your pumps.

Preferred Buyer From

| Location | India ( Haryana only) & All other countries |

PumpDrive: flexible speed control for maximum efficiency

- PumpDrive is the latest generation of KSB’s variable speed systems. It ensures demand-driven pump operation and, hence, maximum energy savings.

- Saving energy with PumpDrive? PumpDrive continuously matches pump speed to system requirements. This ensures energy-efficient and reliable operation of the pumps. Speed control of pumps is highly recommended, especially for systems with fluctuating demand. Demand-driven operation through speed control saves up to 60 percent on energy and increases both the efficiency and the availability of the pump.

- PumpDrive lowers energy costs and reduces the pump’s life cycle costs by controlling the pump input power. Maximum energy savings can be realised by combining PumpDrive with the PumpMeter pump monitoring unit and KSB SuPremE®, the world’s most efficient magnet-less pump motor.

Safe and reliable pump operation

Reliable pump operation requires continuous monitoring of the installation. The pumps' operating status has to be checked frequently. PumpDrive therefore continuously records and processes values, readings and data to monitor the permissible operating range at all times and ensure system availability.

Special features of PumpDrive :

Characteristic curve control and flow rate estimation

PumpDrive monitors the pump’s characteristic curves and estimates the current operating point on the basis of the motor input power and the current speed. This, in turn, allows PumpDrive to detect operation outside the permissible range such as extremely low flow, dry running or overload conditions. Predefined settings allow messages to be output in the case of extremely low flow or overload conditions. Depending on the settings, the pump set is stopped, which protects pumps against failures and damage resulting from operation in an impermissible range.

Continuous flow rate estimation is another essential PumpDrive feature. The flow rate is estimated on the basis of power measurement and the characteristic curve function. The estimated flow rate provides essential information for dynamic pressure compensation and other important functions.

Waste water functions package: optimisation of pump operation in waste water applications

Pressure boosting functions package: constant system pressure thanks to PumpDrive

Redundancy by dual pump management

Thanks to integrated dual pump management, the predefined setpoint for the system is ensured at all times by way of two identical pumps. A distinction is made between two operating modes.

- The setpoint is achieved with one pump operating at rated values. (2 x 100 %)

- The system's rated operating point is achieved with both pumps operating at rated values. (2 x 50 %)

Flexibility in diverse applications

- For every requirement and every application: With a broad range of ratings from 0.37 kW up to 110 kW (up to 1.4 MW available on request), PumpDrive provides for top levels of operating reliability and optimum efficiency in industrial applications much in the same way that the Eco design caters to building services applications.

- PumpDrive's flexibility is also reflected by its mounting options: the speed control system can be mounted to the wall, on the motor or in a control cabinet. The three mounting options allow PumpDrive to be positioned where you need it, meeting individual requirements and conditions on site.

Motor-mounted model

As the new PumpDrive has been perfectly matched to the motors of KSB pumps, it can be mounted directly on motors up to ratings of 55 kW. Benefit of motor mounting: retrofits eliminate the need for installation space in the control cabinet and the search for a suitable section of wall.

Preferred Buyer From

| Location | India ( Haryana only) & All other countries |

Are you looking for the right software for your automation technology?

KSB makes life easy for its customers by providing a software package for servicing and commissioning automation solutions – including WIBU key download for optimum protection.

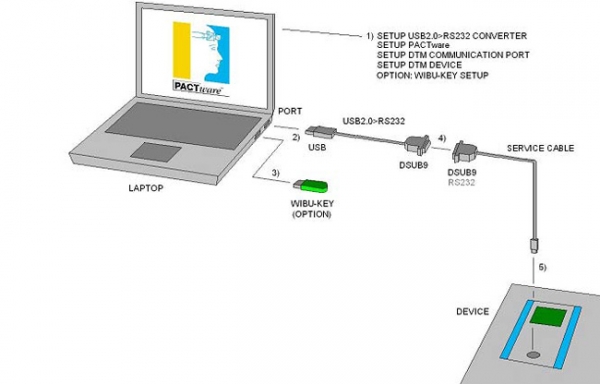

PACTware is a vendor- and fieldbus-independent software for operating field devices. KSB uses this software as a standardised service tool for automation products. With PACTware KSB customers can load drivers (so-called DTMs = Device Type Managers) for field devices from different manufacturers into the service tool. They will then be available for selection in an electronic hardware catalogue. Hardware requirements for the automation tool A laptop or similar can be used for the display and for setting parameters. It has to be connected to the field device via the RS232 or USB interface (only for PumpDrive 2/PumpDrive 2 Eco). PACTware requires a minimum of 100 MB hard disk space and 50 MB main memory. The laptop or PC should have a Pentium III 400 MHz processor and, ideally, an XGA graphics card. It further requires a Microsoft-compatible mouse or equivalent pointing device.

For laptops without RS232 interface, a converter from USB to RS 232 is used; once the converter has been connected to the USB2.0 interface and the corresponding driver has been installed, it serves as an RS232 connection. For PumpDrive 2/PumpDrive 2 Eco this converter is not required. Licence and copy protection with WIBU key Authorisation for changing parameters on the “Service” access level can be granted with a dongle. In order to protect the devices from being parameterised by untrained personnel, KSB uses a protective key (also known as dongle) by the company Wibu-Systems. Connection between parameterisation device (laptop) and terminal device via USB2.0 to RS 232 converter Customers using PumpDrive 2 or PumpDrive 2 Eco (0.37 kW - 4 kW from 31 July 2014) require a parameterisation cable (USB optical) for connecting the device to the laptop.

Preferred Buyer From

| Location | India ( Haryana only) & All other countries |

Discover the optimisation potential of your systems with the KSB® Sonolyzer app

KSB presents a world first: the first app that can hear energy saving potential. Take advantage of potential energy savings With the KSB Sonolyzer® app, you can contact your local KSB specialist directly by e-mail or phone to obtain a detailed efficiency analysis with KSB's Pump Operation Check or SES System Efficiency Service analysis tools. The pump app determines your location and puts you in direct contact with the relevant specialist.

The data package provided by the KSB app is an ideal starting point for obtaining a quick, detailed FluidFuture® analysis and for using the resulting potential savings identified to increase the efficiency of your pumps..

Preferred Buyer From

| Location | India ( Haryana only) & All other countries |

KSB SuPremE® in IE5*: the world's most efficient magnet-less pump motor

The energy diet – good for the environment and your budget: The KSB SuPremE® IE5 motor* is the innovative drive solution for centrifugal pumps and enables an excellent eco-balance.